22D Orgreave Crescent,

Dorehouse Industrial Estate,

Sheffield, S13 9NQ Durham Office

Unit G Gowan House,

Belmont Industrial Estate,

County Durham,

DH1 1TH info@abroofingsolutions.co.uk 0800 917 7663 0114 2799450

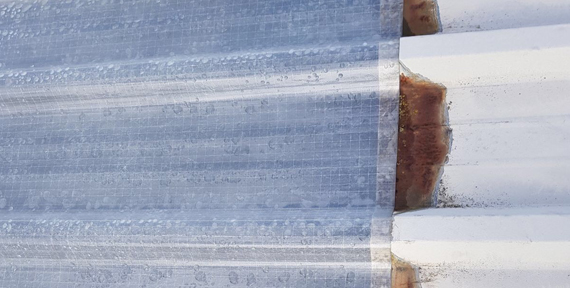

Cut Edge Corrosion

Cut edge corrosion commonly starts as edge peel at the cut edges of a metal sheet. It develops through normal weathering mainly at overlaps and eaves and accelerates through capillary water held in the lap. Pre-finished manufactured roof sheets are cut to length to suit each building or project specifics. Cut edge corrosion usually occurs and can be quite severe in those areas and can cause the sheet coating to de-laminate from the sheet and therefore allowing corrosion to begin. Edge corrosion is a progressive problem and, if detected early (possibly from a planned maintenance, Survey or reactive visit) and effectively treated can prevent costly future roof sheet replacement or future ingress. Cut edge corrosion is commonly included in dilapidation reports when handing back premises to a landlord.

If sheets are damaged from foot traffic or poor installation it is possible for the roof sheet lap to allow ingress via a capillary reaction, again if identified early this can be treated with many of the sheet lap systems available and preventing on-going ingress.

There are many different systems available and AB Roofing solutions are trained and competent in all leading systems enabling us to recommend the correct solution dependant on each site or clients specific circumstances.

Many of the systems we provide carry a guarantee of 10 years+.